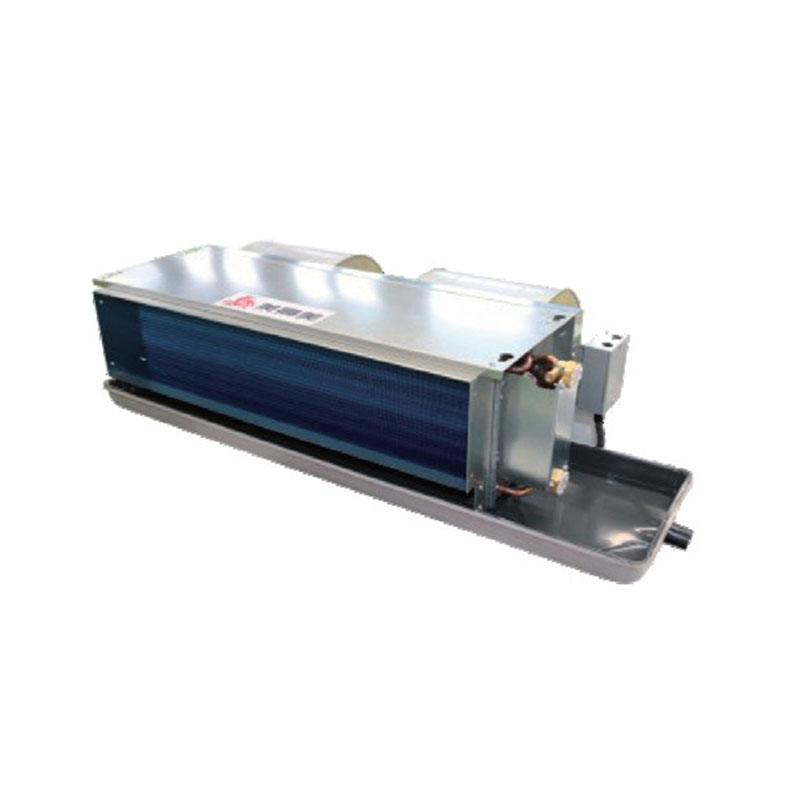

Fan Coil Unit

Additionally, it boasts high efficiency, low noise, easy installation, and maintenance, making it an ideal choice for you.

● The product comes in thirteen specifications, with airflow ranging from 340 to 3400 m³/h and cooling capacity from 1910 to 18000W.

Product Features

● Exquisite Structure, Sturdy, and Durable

This series of fan coil units feature a galvanized steel casing. The condensate water tray is formed integrally using molding technology, eliminating weld seams and points to prevent the common issue of water leakage at welded joints in water trays. The insulation material,

compliant with fire safety regulations, is bonded to the water tray as a whole, resulting in a refined machine structure.

● High Performance, High Efficiency

The heat exchanger of the fan coil unit utilizes high-quality φ9.52mm copper tubes and high-efficiency hydrophilic coated aluminum fins, along with advanced mechanical expansion technology, to achieve optimal contact between the copper tubes and aluminum foils.

Coupled with high air volume, low noise fans to enhance air delivery, the unit can achieve the most ideal heat transfer efficiency. The water collecting header is forged from brass to ensure uniform water distribution and reduce head loss, further improving the overall heat transfer effectiveness of the coil.

● Quiet Operation, Energy Saving

The uniquely designed galvanized multi-blade centrifugal impeller, coupled with a low-noise permanent capacitor motor, achieves optimal matching, undergoing meticulous dynamic balance testing to ensure the unit operates quietly and efficiently. The impeller not only has

high static pressure but also delivers a large airflow while maintaining low noise levels.

● Easy Adjustment, Convenient Maintenance

The motor utilizes rolling bearings for smooth operation. The motor shaft is made of quenched and tempered steel with a surface treated for rust resistance, ensuring durability. Equipped with a three-speed switch or a thermostat, it allows for easy operation and adjustment of indoor airflow and cooling capacity

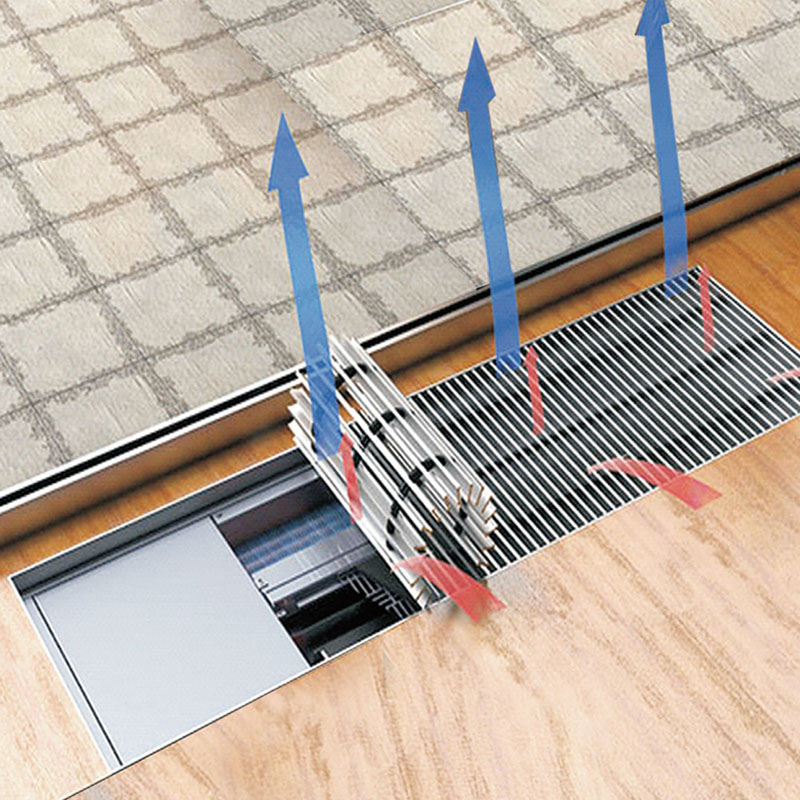

● High Flexibility, Low Installation Cost

The unit is designed to be lightweight, with easy installation of drainage pipes and wiring. The direction of left and right connections and return air can be easily adjusted to accommodate on-site installation requirements.

● Flexible and Convenient Options (Optional) :

Optional high static pressure fan, suitable for installation with ducts

Optional return air box (bottom return air, rear return air) for easy connection to ducts

Optional return air box fresh air inlet

Optional detachable air filter with primary, medium, high efficiency, activated carbon, photocatalyst, etc., for purification purposes

Optional extended water tray for better valve leakage and condensate water storage

Optional stainless steel condensate tray (available in standard and extended versions)

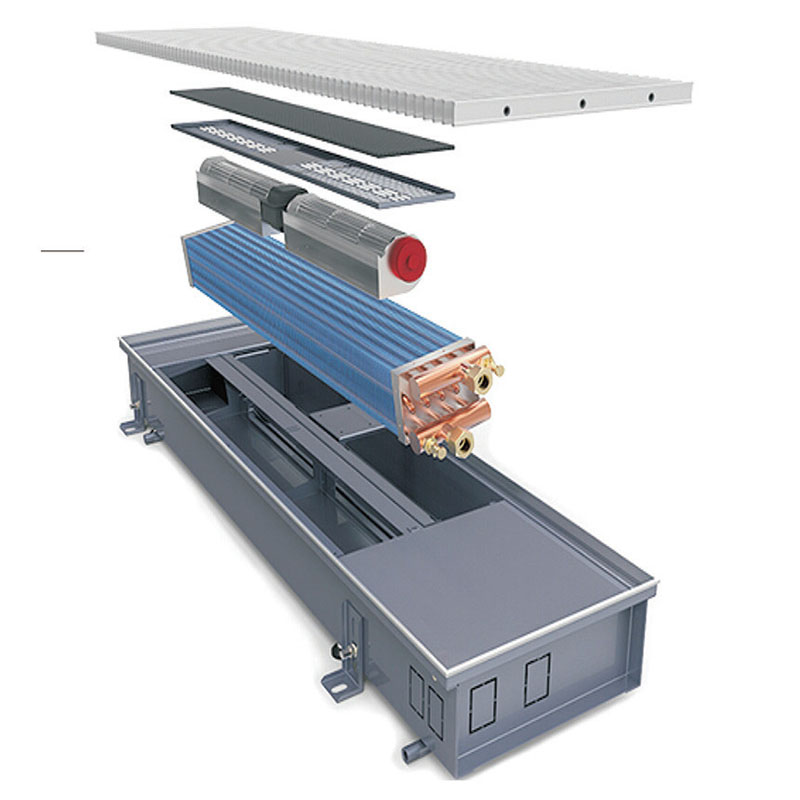

Structural Characteristics

Coil: Ultra-efficient Heat Transfer

Utilizes high-quality φ9.52mm copper tubes and louvered sine wave hydrophilic aluminum fins for heat dissipation, tightly bonded through expansion tubes. The water collecting header is forged from brass, ensuring uniform water distribution and ideal overall heat transfer efficiency.

Casing: Appealing Appearance, Robust Structure

The frame is made of first-grade galvanized steel plate processed by molds, ensuring a solid structure resistant to deformation.

Water Tray: Leak-proof

Utilizing advanced steel plate molds and one-time stamping process, the surface undergoes hot-dip galvanizing and baking paint treatment. 7mm PE insulation is bonded to the water tray, ensuring not only simple processing and attractive appearance but also eliminating the

phenomenon of water leakage at welded joints, greatly extending the service life of the water tray. The unique water tray bracket connected to the coil prevents the possibility of condensation occurring due to screwing on the outer side, thus preserving the insulation layer. The width and length of the water tray can accommodate the piping space for the inlet and outlet water pipes and electric valves to ensure effective water collection.

Motor: High Efficiency, Low Power Consumption

Utilizes a permanent low-noise capacitor motor with fully enclosed rolling bearings, eliminating the need for additional lubricating oil. The base is equipped with rubber shock-absorbing pads to isolate vibrations, reducing operational noise.

Fan: Quiet Operation

The impeller is a high-efficiency, low-noise multi-blade centrifugal fan made of galvanized steel, ensuring high dynamic balance. The main panel and side panel of the fan casing are assembled using Pittsburgh joint form to minimize air leakage and ensure quiet operation.