MFCD Floor Convection Air Conditioning Unit

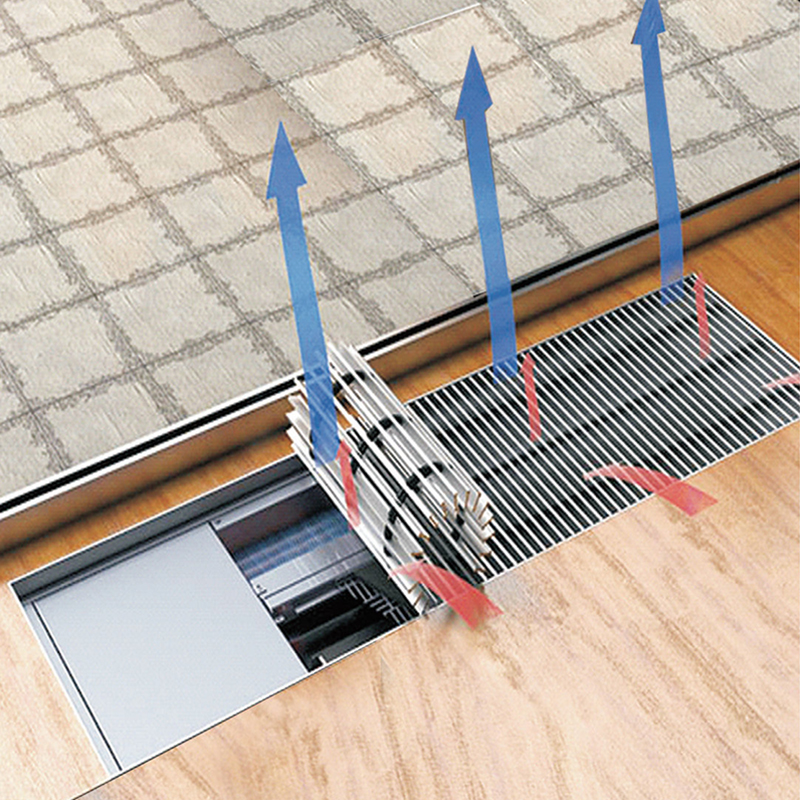

Once installed, the air outlet of the unit aligns with the floor level, unlike traditional fan coil units, thereby not occupying the ceiling space. With floor-level air distribution, it effectively addresses the issue of poor heating performance in large spaces. Widely used in airports, high-speed rail stations, sports arenas, office buildings, private clubs, and other large spaces, it can handle air volumes ranging from 200 to 2000m3/h.

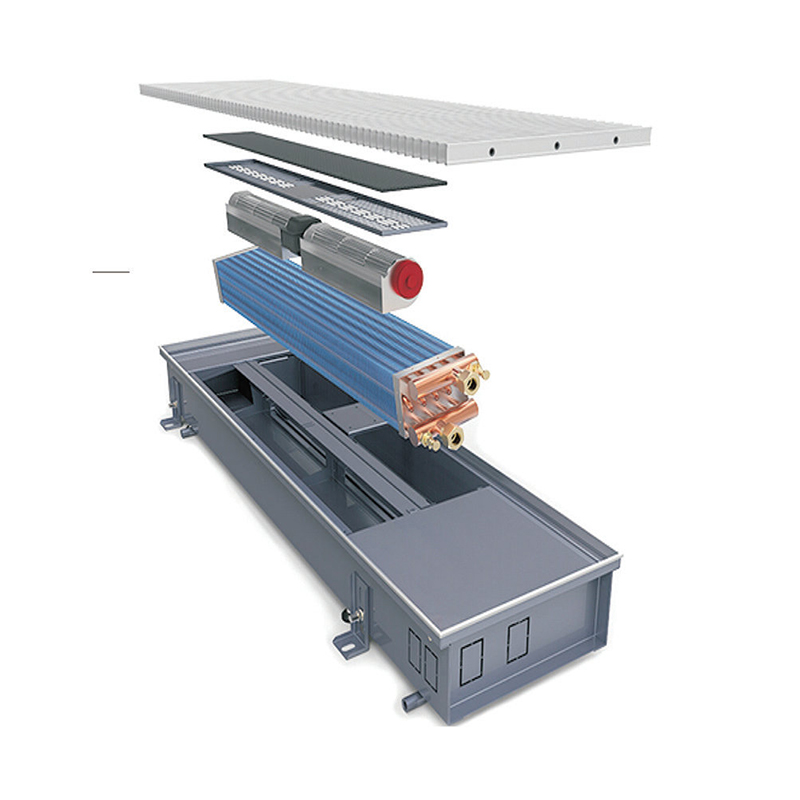

The unit features high-quality fin forming technology, facilitating induced airflow between fins to reduce the boundary layer thickness affecting the heat transfer capability between fins and air. The heat exchanger's main tube, with diameters ranging from 9.52 to 15.88mm and wall thickness from 0.35 to 0.5mm, is formed in one step with the fins through mechanical expansion. The fins have a thickness of 0.115 to 0.35mm. The copper tube portion adopts patented welding with imported anti-oxidation gas protection, enhancing solder flow during welding, ensuring full and void-free welds, and avoiding false welding and chemical corrosion. The coils are securely welded, leak-resistant, and have a long service life. All coils undergo a 2.2MPa high-pressure air pressure test for 20 minutes to ensure normal operation under specified system pressure.

The selection of floor convection air conditioning units is completed using MeiGaoMei's proprietary calculation software. Various fin spacing options such as 5, 7, 8, or 12 per hour are available. While ensuring the cooling and heating loads of the unit, the software selects the most economical heat exchanger fin type and row number for the power type overcurrent gas heat exchanger, minimizing resistance on the coil air side. Different water flow schemes—semi-flow, full flow, and double flow—are coordinated to keep resistance within specified ranges, ensuring uniform distribution of water flow even for devices with significantly different water flow rates, maximizing the application effectiveness of each unit.

Depending on user requirements and environmental conditions, the cabinet sheet metal and heat exchanger surface of the floor air conditioning unit can undergo electrophoretic treatment, with end plates and guards provided for additional thermal insulation protection.