Modular Air Handling Units

Performance Parameters Table for Fresh Air Condition

| Parameters Model | Rated Air Volume (m³/h) |

Applicable Air Volume(m³h) |

Rated Cooling Capacity(KW) |

Rated Heating Capacity(KW) |

Cooling Water Flow Rate(m³/h) |

Cooling Water Resistance(Pa) |

Unit External Dimensions(mm) |

|||||||||

| 4RowS | 6Rows | 8Rows | 4Rows | 6Rows | 8Rows | 4Rows | 6Rows | 8Rows | 4Rows | 6Rows | 8Rows | W | H | |||

| MGMZKW03-JX | 3000 | 2500~3500 | 40 | 49 | 56 | 36 | 42 | 46 | 6.93 | 8.36 | 9.57 | 26.47 | 11.25 | 19.58 | 900 | 800 |

| MGMZKW04-JX | 4000 | 3500~4500 | 51 | 66 | 75 | 49 | 59 | 62 | 8.85 | 11.31 | 12.94 | 25.19 | 41.83 | 18.36 | 1000 | 900 |

| MGMZKW05-JX | 5000 | 4500~5500 | 64 | 81 | 96 | 63 | 70 | 79 | 10.93 | 13.85 | 16.52 | 32.29 | 16.12 | 26.96 | 1150 | 1000 |

| MGMZKW06-JX | 6000 | 5500~6500 | 75 | 97 | 115 | 72 | 85 | 94 | 12.86 | 16.73 | 19.85 | 13.49 | 21.79 | 37.35 | 1150 | 1100 |

| MGMZKW07-JX | 7000 | 6500~7500 | 90 | 122 | 136 | 86 | 100 | 111 | 15.43 | 20.95 | 23.45 | 12.88 | 21.84 | 34.92 | 1200 | 1200 |

| MGMZKW08-JX | 8000 | 7500~8500 | 106 | 142 | 158 | 100 | 116 | 128 | 18.22 | 24.37 | 27.10 | 16.44 | 28.28 | 44.30 | 1200 | 1200 |

| MGMZKW09-JX | 9000 | 8500~9500 | 120 | 160 | 177 | 113 | 131 | 144 | 20.57 | 27.46 | 30.49 | 18.48 | 25.82 | 45.06 | 1400 | 1200 |

| MGMZKW10-JX | 10000 | 9500~11000 | 136 | 179 | 198 | 127 | 147 | 161 | 23.31 | 30.84 | 34.11 | 22.31 | 31.64 | 54.39 | 1400 | 1200 |

| MGMZKW12-JX | 12000 | 11000~13000 | 164 | 216 | 239 | 153 | 177 | 194 | 28.24 | 37.20 | 41.11 | 21.91 | 30.80 | 53.03 | 1400 | 1400 |

| MGMZKW15-JX | 15000 | 14000~17000 | 209 | 273 | 282 | 194 | 223 | 232 | 36.00 | 47.00 | 48.57 | 31.62 | 46.22 | 22.26 | 1600 | 1400 |

| MGMZKW20-JX | 20000 | 18000~22000 | 289 | 349 | 386 | 259 | 292 | 315 | 49.77 | 60.10 | 66.30 | 44.25 | 28.93 | 30.52 | 1900 | 1750 |

| MGMZKW25-UX | 25000 | 23000~27000 | 353 | 431 | 476 | 317 | 361 | 391 | 60.66 | 74.04 | 81.84 | 46.54 | 31.08 | 32.66 | 1900 | 2000 |

| MGMZKW30-JX | 30000 | 28000~32000 | 407 | 541 | 593 | 371 | 449 | 183 | 69.99 | 92.97 | 101.94 | 20.20 | 48.36 | 48.53 | 2350 | 2000 |

| MGMZKW35-JX | 35000 | 33000~37000 | 511 | 631 | 691 | 433 | 524 | 563 | 87.95 | 108.44 | 118.86 | 27.57 | 62.97 | 61.80 | 2600 | 2000 |

| MGMZKW40-JX | 40000 | 38000~42000 | 551 | 725 | 853 | 506 | 602 | 646 | 94.80 | 124.71 | 146.61 | 26.05 | 64.36 | 62.99 | 2600 | 2000 |

| MGMZKW45-JX | 45000 | 43000~47000 | 626 | 819 | 921 | 573 | 679 | 729 | 107.73 | 140.84 | 158.44 | 31.64 | 80.19 | 82.12 | 2800 | 2200 |

| NGMZKW50-JX | 50000 | 48000~55000 | 699 | 921 | 1025 | 638 | 756 | 811 | 120.25 | 156.86 | 176.34 | 31.35 | 96.05 | 78.64 | 2800 | 2450 |

| MGMZKW60-JX | 60000 | 55000~65000 | 857 | 1105 | 1236 | 777 | 914 | 979 | 147.35 | 190.05 | 213.08 | 36.79 | 94.04 | 91.91 | 3000 | 2700 |

| MGMZKW70-JX | 70000 | 65000~75000 | 1003 | 1290 | 1666 | 907 | 1067 | 1143 | 172.53 | 221.92 | 286.54 | 43.55 | 114.08 | 109.73 | 3350 | 2950 |

| MGMZKW80-JX | 80000 | 75000~85000 | 1174 | 1520 | 1731 | 1054 | 1231 | 1315 | 201.86 | 261.38 | 297.65 | 49.06 | 132.33 | 122.63 | 3580 | 3200 |

| MGMZKW90-JX | 90000 | 85000~95000 | 1310 | 1702 | 1941 | 1178 | 1380 | 1476 | 225.33 | 292.73 | 333.83 | 57.93 | 161.12 | 154.17 | 3800 | 3250 |

| MGMZKW100-JX | 100000 | 95000~110000 | 1490 | 1913 | 2093 | 1285 | 1547 | 1652 | 256.49 | 328.95 | 359.99 | 63.56 | 176.61 | 159.81 | 4050 | 3450 |

| MGMZKW120-JX | 120000 | 110000~130000 | 1775 | 2285 | 2502 | 1531 | 1850 | 1977 | 305.27 | 392.94 | 430.34 | 73.75 | 210.59 | 188.26 | 4280 | 3680 |

Return Air Condition Performance Parameters Table

| Parameters Model | Rated Air Volume (m³/h) |

Applicable Air Volume(m³h) |

Rated Cooling Capacity(KW) |

Rated Heating Capacity(KW) |

CoolingWater Flow Rate(m³/h) |

Cooling Water Resistance(Pa) |

Unit External Dimensions(mm) |

|||||||||

| 4Rows | 6Rows | 8Rows | 4Rows | 6Rows | 8Rows | 4Rows | 6Rows | 8Rows | 4Rows | 6Rows | 8Rows | W | H | |||

| MGMZKW03-JT | 3000 | 2500~3500 | 17.8 | 23.2 | 26.9 | 29 | 36 | 40 | 3.06 | 4.00 | 4.63 | 10.13 | 12.63 | 25.08 | 900 | 800 |

| MGMZKW04-JT | 4000 | 3500~4500 | 24.5 | 31.6 | 34.9 | 39 | 48 | 53 | 4.21 | 5.43 | 6.00 | 9.69 | 11.82 | 24.82 | 1000 | 900 |

| MGMZKW05-JT | 5000 | 4500~5500 | 27.6 | 39.4 | 46.5 | 50 | 63 | 69 | 4.75 | 6.78 | 7.99 | 12.36 | 22.20 | 39.56 | 1150 | 1000 |

| MGMZKW06-JT | 6000 | 5500~6500 | 35.1 | 47.4 | 55.7 | 60 | 75 | 82 | 6.03 | 8.16 | 9.58 | 17.40 | 30.45 | 53.08 | 1150 | 1100 |

| MGMZKW07-JT | 7000 | 6500~7500 | 42.3 | 56.4 | 66 | 72 | 88 | 97 | 7.27 | 9.69 | 11.35 | 15.70 | 28.50 | 49.72 | 1200 | 1200 |

| MGMZKW08-JT | 8000 | 7500~8500 | 47.3 | 63.2 | 76.2 | 83 | 105 | 111 | 8.13 | 10.87 | 13.11 | 20.44 | 37.73 | 64.46 | 1200 | 1200 |

| MGMZKW09-JT | 9000 | 8500~9500 | 54.3 | 64.4 | 76.8 | 94 | 107 | 118 | 9.34 | 11.08 | 13.21 | 23.67 | 36.27 | 64.41 | 1400 | 1200 |

| MGMZKW10-JT | 10000 | 9500~11000 | 60.2 | 77.5 | 86.1 | 105 | 118 | 132 | 10.35 | 13.33 | 14.81 | 28.35 | 44.33 | 79.23 | 1400 | 1200 |

| MGMZKW12-JT | 12000 | 11000~13000 | 73.1 | 100.1 | 104 | 126 | 142 | 159 | 12.58 | 17.21 | 17.89 | 27.93 | 42.16 | 77.46 | 1400 | 1400 |

| MGMZKW15-JT | 15000 | 14000~17000 | 88 | 115 | 143 | 154 | 177 | 198 | 15.13 | 19.73 | 24.57 | 38.93 | 14.76 | 31.81 | 1600 | 1400 |

| MGMZKW20-JT | 20000 | 18000~22000 | 112 | 159 | 187 | 200 | 251 | 275 | 19.20 | 27.31 | 32.09 | 50.82 | 27.04 | 47.45 | 1900 | 1750 |

| MGMZKW25-JT | 25000 | 23000~27000 | 131 | 195 | 230 | 242 | 310 | 341 | 22.57 | 33.49 | 39.51 | 51.28 | 28.87 | 50.61 | 1900 | 2000 |

| MGMZKW30-JT | 30000 | 28000~32000 | 189 | 248 | 287 | 322 | 384 | 417 | 32.47 | 42.62 | 49.38 | 26.41 | 46.92 | 78.91 | 2350 | 2000 |

| MGMZKW35-JT | 35000 | 33000~37000 | 220 | 289 | 334 | 374 | 447 | 486 | 37.81 | 49.72 | 57.49 | 33.63 | 61.73 | 102.06 | 2600 | 2000 |

| MGMZKW40-JT | 40000 | 38000~42000 | 255 | 333 | 384 | 430 | 514 | 557 | 43.82 | 57.28 | 66.10 | 34.67 | 63.35 | 104.49 | 2600 | 2000 |

| MGMZKW45-JT | 45000 | 43000~47000 | 289 | 377 | 433 | 485 | 579 | 627 | 49.66 | 64.76 | 74.53 | 42.66 | 79.76 | 129.57 | 2800 | 2200 |

| MGMZKW50-JT | 50000 | 48000~55000 | 323 | 420 | 483 | 541 | 644 | 698 | 55.48 | 72.18 | 83.02 | 42.33 | 78.78 | 128.05 | 2800 | 2450 |

| MGMZKW60-JT | 60000 | 55000~65000 | 395 | 510 | 584 | 656 | 778 | 841 | 67.96 | 87.70 | 00.47 | 50.40 | 94.72 | 152.07 | 3000 | 2700 |

| MGMZKW70-JT | 70000 | 65000~75000 | 462 | 896 | 647 | 765 | 908 | 957 | 79.39 | 102.44 | 111.28 | 60.29 | 115.78 | 46.57 | 3350 | 2950 |

| MGMZKW80-JT | 80000 | 75000~85000 | 541 | 667 | 751 | 887 | 1027 | 1102 | 93.05 | 114.72 | 129.08 | 68.91 | 56.02 | 52.47 | 3580 | 3200 |

| MGMZKW90-JT | 90000 | 85000~95000 | 602 | 747 | 841 | 989 | 1151 | 1237 | 103.47 | 128.49 | 144.68 | 81.92 | 68.21 | 62.96 | 3800 | 3250 |

| MGMZKW100-T | 100000 | 95000~110000 | 687 | 845 | 949 | 1117 | 1292 | 1385 | 118.10 | 145.35 | 63.17 | 91.10 | 75.40 | 68.88 | 4050 | 3450 |

| MGMZKW120-T | 120000 | 10000~130000 | 742 | 1009 | 1134 | 1265 | 1546 | 1658 | 127.65 | 173.55 | 195.00 | 27.01 | 89.88 | 81.11 | 4280 | 3680 |

● Complete Specifications

This series of units has comprehensive air treatment functions, including air mixing, filtration, heating, cooling, dehumidification, humidification, noise reduction, heat recovery, and automatic control. The air volume ranges from 2000 to 200,000m³/h, and there are various structural types available such as ceiling-mounted, horizontal, and vertical. With complete functional sections, flexible selection, and convenient combination, it meets diverse needs.

● Quality Assurance

Advanced production equipment and processes create a solid foundation for product quality. Strict production processes, in-process inspections, and factory inspections provide institutional guarantees for product quality. Rigorous supplier qualification reviews and incoming inspections of components provide excellent technical support for the overall product quality.

● Optimized Design, Reliable Data

This series of units adopts computer-assisted optimization design and utilizes performance testing platforms certified by national authoritative institutions to provide comprehensive, accurate, and rigorous test data for unit experiments. It enables analysis of performance parameters under specific operating condition

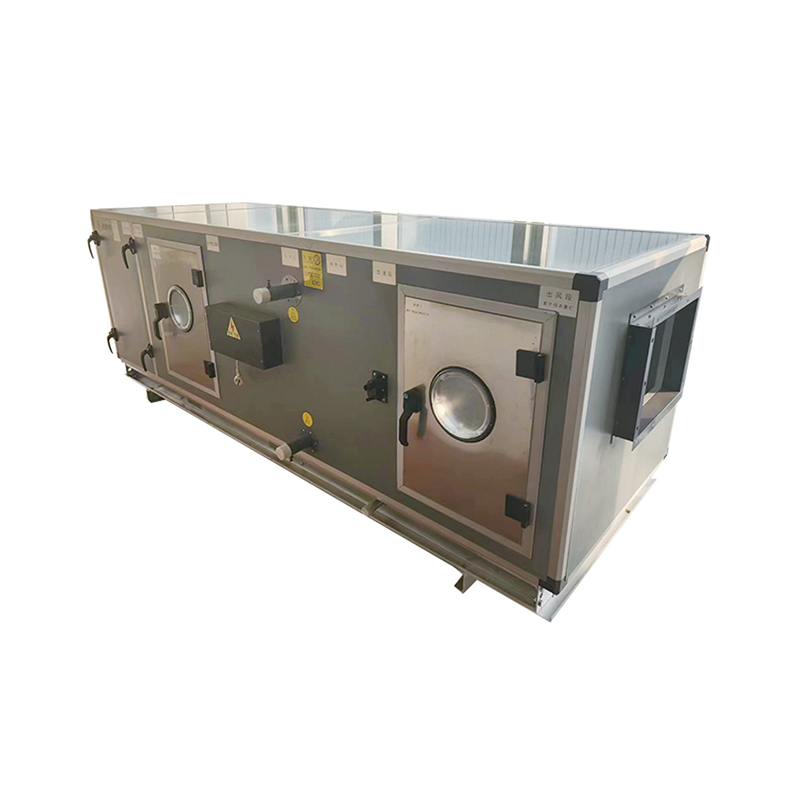

● Attractive Appearance

dimensions and meticulous craftsmanship for an appealing appearance. The unit features quick installation, simple operation, and easy maintenance, making it suitable for a wide range of residential and industrial applications.

Unit Characteristics

● This series of units is divided into multiple different model ranges based on the volume of air they handle. Each model range adopts the most suitable structural form, fully reflecting structural optimization and scientific design.

● The unit is designed with exhaust at the highest point and drainage at the lowest point inside, ensuring safe operation of the unit.

● Box Structure

The entire box structure consists of a frame and double-layer panels. The outer panel is made of high-quality color steel plate material, which is corrosion-resistant, rust-proof, aesthetically pleasing, and durable, with a long service life. The inner layer is made of galvanized steel plate. The intermediate wall panel is filled with high-density (36 kg/cm³) polyurethane foam insulation material, which is completely free of CFCs. It has excellent insulation performance with a thermal conductivity coefficient of 0.189 Kal/m.h.℃, preventing condensation.

It also has sound-absorbing and noise-reducing functions and is available in different panel thicknesses such as 25mm, 35mm, and 50mm.

● Internal Structure

Special maintenance doors for the box with good sealing effects and easy operation. Dual-slope condensate pan structure to ensure rapid condensate drainage. Specially designed and researched aluminum alloy profile structure and anti-cold bridge structural components to ensure insulation and thermal insulation of the box, preventing the occurrence of cold bridges. This design maximizes the reduction of air leakage rates and promotes economic energy savings

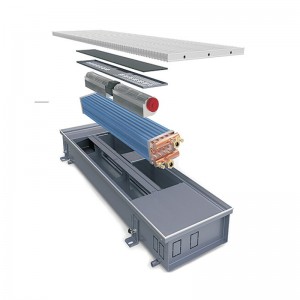

● The selected accessories include

Unique corrugated aluminum fins tightly connected to copper tubes using mechanical expansion tube method, ensuring maximum heat exchange efficiency.

Coil undergoes leakage test under a pressure of 2.5MPa.

The fan is a dual-inlet low-noise centrifugal fan. The impeller and belt undergo strict static and dynamic balance calibration in the factory, ensuring smooth operation, high efficiency, and low noise.

The primary filter adopts a plate structure with efficiency of G3 grade or above. The medium efficiency filter adopts a bag structure with efficiency of F5 grade or above. The sub-high efficiency filter can be either bag or pleated structure with efficiency ranging from F9 to H10 grade.

Various humidification methods can be matched, such as dry steam humidification, wet film humidification, electrode humidification, etc.

Variable frequency drive can be installed according to customer requirements to achieve variable air volume adjustment for the unit.